Different stages of gold ore beneficiation require different gold ore beneficiation equipment. For example, crushers are needed for the crushing stage, ball mills and vibrating screens are needed for the grinding and screening stage, and depending on the gold ore beneficiation method, flotation equipment and gravity separation equipment may be needed for the beneficiation stage.

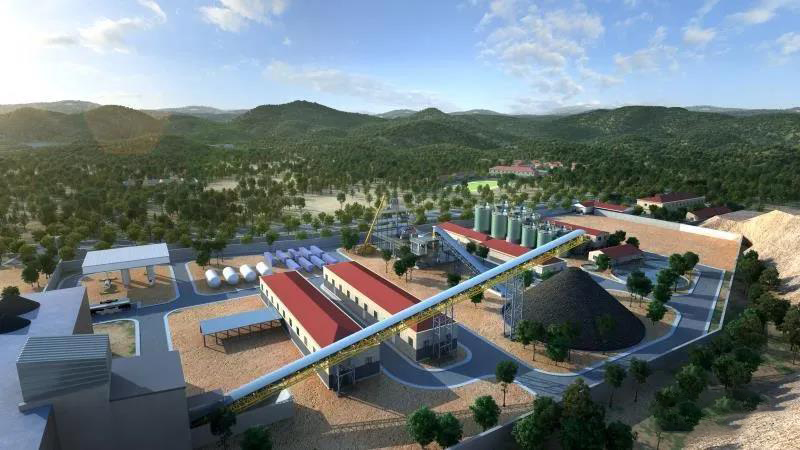

Gold Ore Beneficiation Equipment

The gold ore beneficiation process involves multiple stages, including crushing, grinding, classification, separation, and leaching. Each stage requires corresponding equipment to ensure efficient gold extraction.

Factors Affecting Mineral Processing Efficiency

The efficiency of gold ore mineral processing is influenced by a combination of factors, primarily including ore properties, process parameters, and operational management levels.

The form of gold in the ore, particle size, and distribution characteristics directly determine the difficulty of mineral processing and recovery rates, serving as the foundational factors influencing mineral processing efficiency.

Various process control parameters during mineral processing significantly impact the efficiency of gold concentration. For example, the solid-liquid ratio, pH value, and temperature of the slurry; the type and dosage of flotation reagents; and the process conditions for cyanide leaching all directly affect the efficiency of gold extraction.

The operational technical proficiency at the mineral processing site and the operational status of equipment are also critical factors in ensuring the stability and recovery rate of mineral processing. Proper management, appropriate operations, and efficient equipment operation contribute to improving overall mineral processing efficiency and gold recovery rates.

Copyright © 2020 Henan Mingheng Heavy Industry Machinery Co., Ltd. Power by yisainuo